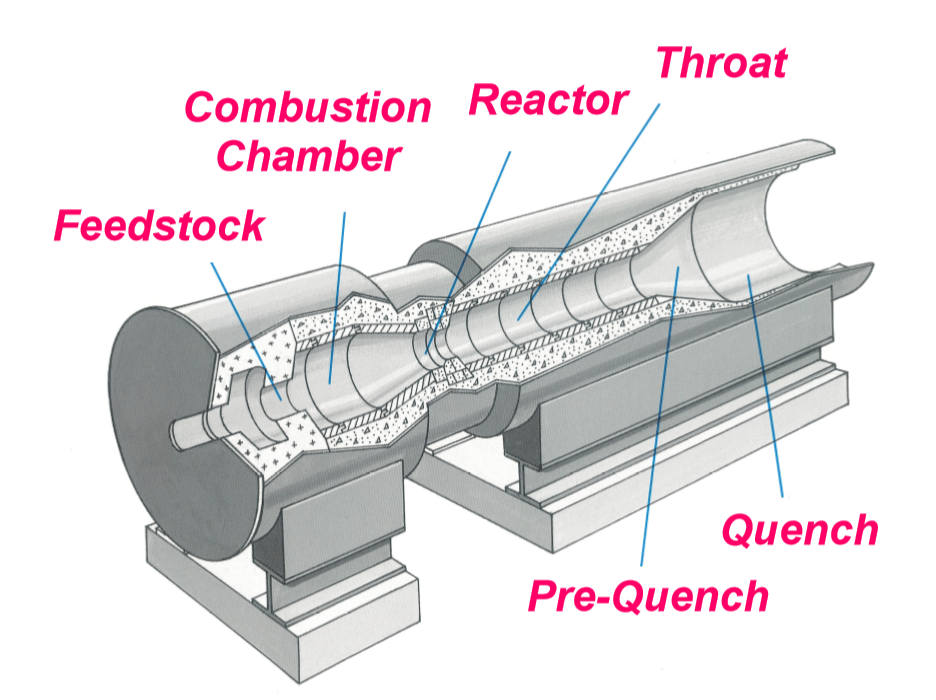

Carbon Black Reactor

In refineries and petrochemical plants, the need for high quality, dependable monolithic, and brick is a constant. Because we have serviced the refining and Petrochemical industries for many years, we are able to offer these industries specialty refractories. These refractories are designed to withstand the extreme service conditions experienced in the carbon black reactor processes.

Resco Products provides high-quality industry-standard refractory. Fully customized solutions for hot face and back up refractory layers are designed for select cases. Refractories are ideal within your hard black and soft black reactors.

Your Resco carbon black reactor specialist will evaluate your carbon black production and manufacturing process to recommend a custom solution. Providing superior product quality, longer campaigns, and higher yield rates.

Refractories for Carbon Black Reactors

The most common carbon black reactor products Resco sells are the Rescal 90XD for inside the throat and pre-quench primary lining, along with Patriot and LW-26 for the quench-back up only. Contact Resco for more information on these and other HPI/Petrochem products.